Fire extinguishers are a critical component of any effective fire safety plan, providing a vital first line of defense against small fires before they can spread. While there are many types available, choosing the right one is essential for effective fire prevention. This article will compare CO2 fire extinguishers and dry powder fire extinguishers, helping you understand their key differences, advantages, and disadvantages to make an informed decision.

What is a CO2 Fire Extinguisher?

A CO2 fire extinguisher contains compressed liquid carbon dioxide (CO2). When the extinguisher is discharged, the liquid CO2 rapidly expands and turns into a gas, which is expelled from the horn as a white, cold "snow" or mist. This gas works by displacing the oxygen around the fire, effectively suffocating it. The cold temperature of the CO2 also helps to cool the fuel, which further aids in extinguishing the fire.

Effectiveness on Fire Types

CO2 extinguishers are most effective on the following fire classes:

-

Class B Fires: Involving flammable liquids and gases such as gasoline, oil, and paint.

-

Class C Fires: Involving energized electrical equipment. The CO2 gas is non-conductive, making it safe to use on live electrical fires without the risk of electrocution.

They are not effective on Class A fires (ordinary combustibles like wood, paper, and fabric) because the fire can re-ignite after the CO2 dissipates, as it doesn't have a lasting cooling or soaking effect.

Advantages of CO2 Extinguishers

-

Leaves No Residue: CO2 is a gas, so it evaporates completely, leaving no mess behind. This makes it ideal for use in environments with sensitive equipment, such as server rooms, labs, or offices.

-

Safe for Electrical Fires: Because the gas is non-conductive, it's the top choice for extinguishing fires involving electrical equipment without causing further damage or risking electrocution.

Disadvantages of CO2 Extinguishers

-

Limited Range: The gas disperses quickly, so the extinguisher has a limited effective range, especially in open or windy areas.

-

Suffocation Risk: Since the extinguisher works by displacing oxygen, using it in a small, enclosed space can pose a suffocation risk to the user and anyone else in the area.

-

Frostbite Risk: The horn and discharged gas are extremely cold (as low as -109°F or -78°C), and can cause severe frostbite if touched without proper handling or a frost-free horn.

What is a Dry Powder Fire Extinguisher?

A dry powder fire extinguisher, also known as a dry chemical extinguisher, contains a fine powder, typically a mix of chemicals like monoammonium phosphate or sodium bicarbonate. When discharged, this powder is propelled by compressed gas (often nitrogen) and creates a cloud that coats the burning material. It works in two ways: by separating the fuel from the oxygen supply, effectively smothering the fire, and by interrupting the chemical reaction that allows the fire to burn.

Effectiveness on Fire Types

Dry powder extinguishers are highly versatile and are effective on a wide range of fires:

-

Class A Fires: Involving ordinary combustible materials like wood, paper, and textiles.

-

Class B Fires: Involving flammable liquids such as gasoline, oil, and paint.

-

Class C Fires: Involving flammable gases such as propane and butane.

-

Electrical Fires: They can be used on electrical fires, although CO2 is often a preferred choice for sensitive equipment due to the residue.

Specialized dry powder extinguishers are also available for Class D fires, which involve combustible metals like magnesium or titanium.

Advantages of Dry Powder Extinguishers

-

Versatility: They are often called "ABC" extinguishers because they can be used on Class A, B, and C fires, making them a good all-around choice for environments with varied fire risks.

-

Effective on Class A Fires: Unlike CO2 extinguishers, the powder has a lasting effect on solid materials, helping to prevent re-ignition.

Disadvantages of Dry Powder Extinguishers

-

Leaves a Messy Residue: The powder is messy and can be difficult and time-consuming to clean up.

-

Can Damage Sensitive Equipment: The fine, abrasive, and sometimes corrosive powder can cause significant damage to electronics, machinery, and sensitive equipment.

-

Reduced Visibility: When discharged, the powder creates a thick cloud that can obscure vision and make it difficult to see an escape route, especially in an enclosed space.

-

Respiratory Irritation: Inhaling the powder can cause respiratory irritation, making it unsafe to use in poorly ventilated or small, enclosed areas.

Key Differences Between CO2 and Dry Powder Extinguishers

1. Fire Types and Effectiveness

-

CO2 Extinguishers: These are specifically designed for Class B (flammable liquids and gases) and Class C (electrical) fires.

They are highly effective on these types of fires because they displace oxygen, suffocating the flames. The cold temperature of the discharged CO2 also helps to cool the fire. However, they are not recommended for Class A fires (ordinary combustibles like wood and paper) because the fire can re-ignite easily once the CO2 gas dissipates. -

Dry Powder Extinguishers: These are more versatile and are often labeled as ABC extinguishers, meaning they are effective on Class A, B, and C fires.

They work by creating a physical barrier between the fuel and oxygen and by interrupting the chemical chain reaction of the fire. Their versatility makes them a popular all-purpose choice, and certain specialized dry powder extinguishers can even handle Class D fires involving combustible metals.

2. Residue and Cleanup

-

CO2 Extinguishers: A major advantage of CO2 extinguishers is that they leave no residue.

The carbon dioxide gas simply dissipates into the atmosphere after use. This makes them the preferred choice for environments with sensitive or expensive equipment, such as computer server rooms, laboratories, and electrical control panels, where a messy cleanup could cause more damage than the fire itself. -

Dry Powder Extinguishers: The dry chemical agent leaves behind a messy, abrasive, and sometimes corrosive residue.

This powder can be difficult to clean up and can damage sensitive electronics, machinery, and soft furnishings. The cleanup process can be extensive and costly, requiring specialized equipment.

3. Safety Risks

-

CO2 Extinguishers: A primary safety concern with CO2 extinguishers is the risk of suffocation.

As they work by displacing oxygen, using them in a confined or poorly ventilated space can be dangerous to anyone in the area. Additionally, the discharged CO2 is extremely cold, and direct contact with the horn or the gas stream can cause severe frostbite. Users must be trained to hold the extinguisher by its insulated handle. -

Dry Powder Extinguishers: The main safety risk is respiratory irritation. The fine powder can be inhaled, causing coughing, shortness of breath, or irritation to the nose and throat, especially in enclosed areas. The powder cloud can also significantly reduce visibility, which can make it difficult to find an exit or an escape route.

4. Environmental Impact

-

CO2 Extinguishers: The CO2 released from these extinguishers is a greenhouse gas, contributing to global warming. While the amount from a single extinguisher is small, the cumulative effect can be a concern for some.

-

Dry Powder Extinguishers: The chemical components of the powder can have environmental implications.

If not properly cleaned up, the residue can contaminate soil and water sources, potentially affecting local ecosystems.

| Feature | CO2 Fire Extinguisher | Dry Powder Fire Extinguisher |

| Fire Classes | Best for Class B (flammable liquids) and Class C (electrical). | Highly versatile; effective on Class A (solids), B, and C fires. Some specialized types for Class D (combustible metals). |

| Extinguishing Mechanism | Displaces oxygen, suffocating the fire. The cold temperature also cools the fuel. | Smothers the fire by creating a barrier between fuel and oxygen. Interrupts the chemical reaction. |

| Residue | Leaves no residue. The gas dissipates completely. | Leaves a messy, abrasive residue that is difficult to clean and can be corrosive to equipment. |

| Safety Risks | Suffocation risk in enclosed spaces due to oxygen displacement. Frostbite risk from the extremely cold horn and gas. | Respiratory irritation from inhaling the powder, especially in enclosed spaces. Reduced visibility due to the powder cloud. |

| Environmental Impact | CO2 is a greenhouse gas, contributing to global warming upon release. | The chemical composition of the powder can have potential environmental concerns, such as contaminating soil and water if not contained and cleaned up properly. |

| Primary Applications | Computer rooms, laboratories, data centers, kitchens where sensitive equipment is present and cleanup is a concern. | Garages, workshops, industrial settings, vehicles where versatility is more important than a residue-free environment. |

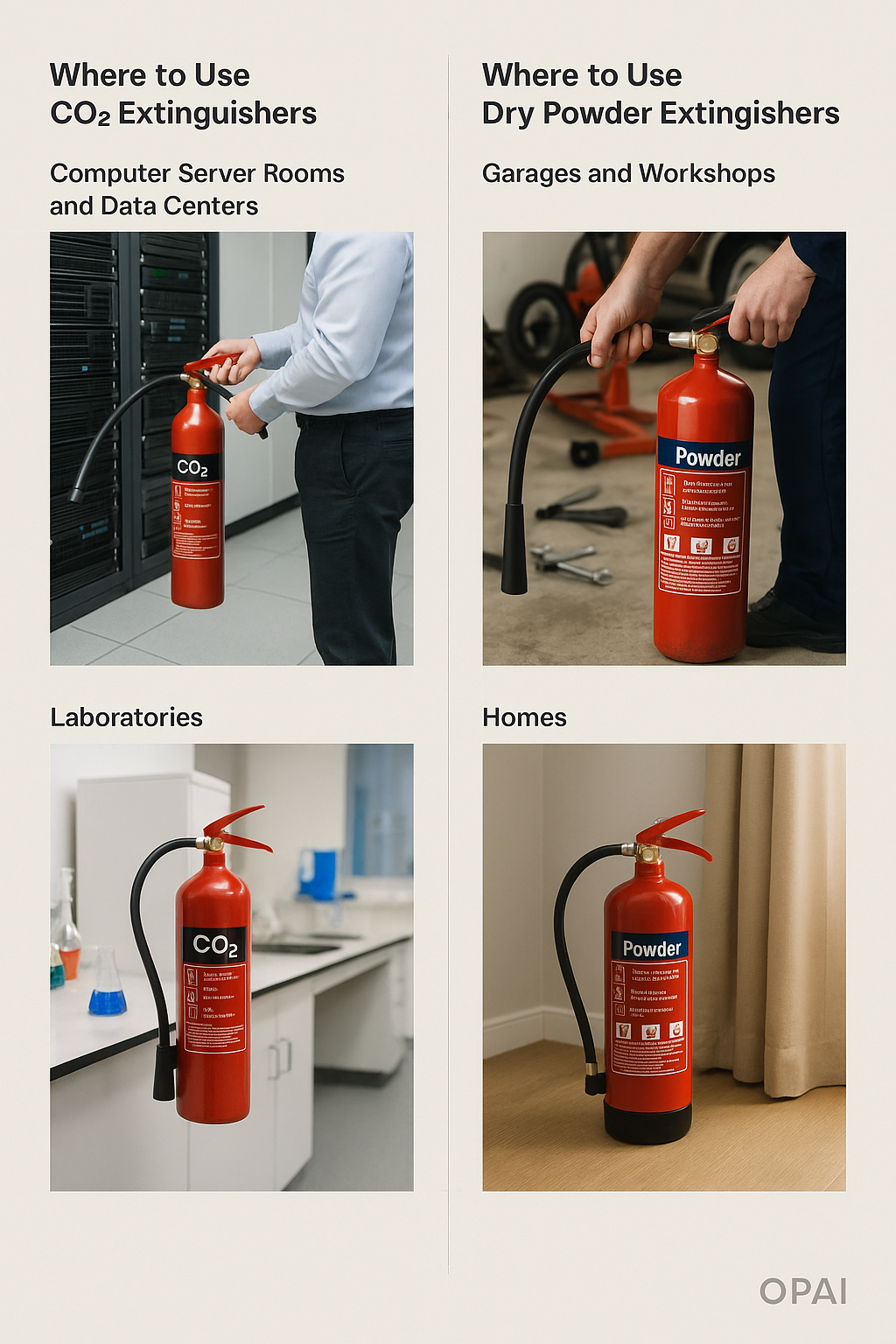

Applications: Where to Use Each Type

The distinct properties of CO2 and dry powder extinguishers make them suitable for different environments. Choosing the right one depends on the specific fire risks and the type of equipment or materials present.

Where to Use CO2 Extinguishers

Due to their residue-free operation and non-conductive nature, CO2 extinguishers are the ideal choice for environments where cleanliness and the protection of sensitive equipment are top priorities.

-

Computer Server Rooms and Data Centers: These areas are filled with expensive, delicate electronic equipment. A dry powder extinguisher would cause irreparable damage. CO2 is perfect because it extinguishes electrical fires without leaving any residue.

-

Laboratories: Labs often contain flammable liquids and delicate scientific instruments. A CO2 extinguisher can handle chemical fires (Class B) without contaminating the lab or damaging expensive apparatus.

-

Kitchens: While kitchen fires can involve combustible materials, they are more often centered on flammable cooking oils and fats (Class B). A CO2 extinguisher can tackle these fires without creating a messy cleanup on kitchen surfaces or in food preparation areas.

-

Offices: For fires involving computers, printers, and other electrical office equipment, a CO2 extinguisher is the safest and most effective option.

Where to Use Dry Powder Extinguishers

The versatility and powerful extinguishing capabilities of dry powder extinguishers make them suitable for general-purpose use in a variety of settings where a residue is less of a concern.

-

Garages and Workshops: These environments often contain a mix of materials, including wood, paper, gasoline, and other flammable liquids. A single ABC dry powder extinguisher can handle all of these fire types, making it a highly practical choice.

-

Vehicles: A small dry powder extinguisher is an excellent choice for a car, truck, or boat. It can extinguish fires in the engine bay (flammable liquids), the interior (solid materials), or from a fuel leak.

-

Industrial and Construction Sites: Due to the variety of materials and machinery on site, a dry powder extinguisher's multi-purpose capability is invaluable.

-

Homes: For general household use, an ABC dry powder extinguisher is a common and effective choice for handling the most likely fire scenarios, such as fires involving a burning curtain, a small electrical appliance, or a forgotten can of paint.

Factors to Consider When Choosing

Choosing the right fire extinguisher goes beyond just knowing the different types. You need to consider several practical factors to ensure the extinguisher is a good fit for your environment and for the people who might need to use it.

Size and Weight

Fire extinguishers come in a range of sizes, typically measured in pounds of extinguishing agent. The size and weight directly impact their portability and ease of use. A smaller, lighter extinguisher (like a 5 lb model) is easier for most people to handle, making it a good choice for a home kitchen or office. A larger, heavier extinguisher (like a 10 lb or 15 lb model) offers more extinguishing power and a longer discharge time, making it better for a larger space like a workshop or garage where a fire might grow quickly.

Ease of Use and Maintenance

-

CO2 Extinguishers: These are relatively straightforward to use, but the user must be aware of the suffocation risk and the danger of frostbite from the discharge horn. They do not require a shake test. Maintenance involves a regular visual inspection to ensure the cylinder and hose are in good condition. Because they don't have a pressure gauge, their charge is checked by weighing the cylinder to ensure it meets the manufacturer's specified weight.

-

Dry Powder Extinguishers: These are generally easy to operate using the P.A.S.S. method (Pull, Aim, Squeeze, Sweep). For maintenance, some dry powder extinguishers need to be shaken periodically (typically monthly) to prevent the powder from settling and compacting, which can hinder its discharge. They also have a pressure gauge that should be checked monthly to ensure the needle is in the green zone, indicating it is properly pressurized.

Cost

The initial cost of an extinguisher is a factor, but so are long-term considerations like maintenance and potential cleanup costs.

-

CO2 Extinguishers: Generally have a higher initial purchase price compared to dry powder models of a similar size. However, because they leave no residue, they have a lower "cost of use" in terms of potential cleanup and damage to equipment.

-

Dry Powder Extinguishers: Are typically more affordable upfront, making them a budget-friendly option for general-purpose use. However, the potential for extensive and costly cleanup after use, especially if sensitive equipment is damaged, should be factored in.

Specific Hazards Present in the Environment

This is arguably the most critical factor. You must match the extinguisher to the specific types of fires that are most likely to occur in the location. For example, a home garage with a car and workshop materials would benefit most from a versatile dry powder extinguisher. In contrast, a modern office with computers and other electronics would be best served by a CO2 extinguisher to protect the valuable equipment.

Best Recommended Products

This section would typically feature specific product recommendations. However, to maintain the requested format and avoid mentioning specific brands or shopping websites, we will instead describe the ideal characteristics and parameters of fire extinguishers that would be best for different use cases, allowing the reader to find suitable products on their own.

CO2 Fire Extinguisher Features to Look For

When selecting a CO2 extinguisher for a computer room, lab, or kitchen, look for models with the following specifications:

-

Size: A 5-10 lb extinguisher is a common and effective size for most office and lab environments, offering a good balance between portability and extinguishing power. A smaller 2.5 lb model may be suitable for a small home kitchen.

-

Rating: The extinguisher should have a UL/EN rating for Class B and C fires, which will be clearly marked on the label. This rating indicates its effectiveness on flammable liquids and electrical fires.

-

Non-Conductive Horn: An insulated, non-conductive discharge horn is a critical safety feature to prevent electrical shock.

-

Materials: Look for a durable aluminum or steel cylinder and a sturdy valve assembly for longevity.

Dry Powder Fire Extinguisher Features to Look For

For a garage, workshop, or vehicle, an ABC dry powder extinguisher with the following characteristics is a great choice:

-

Size: A 2.5 lb or 5 lb extinguisher is a practical size for vehicles and smaller workshops. For a larger garage or industrial space, a 10 lb or 20 lb model would provide more power and duration.

-

Rating: The extinguisher should be rated for Class A, B, and C fires, typically indicated by a rating like "ABC" or "A:B:C" on the label.

-

Pressure Gauge: A readily visible pressure gauge is essential. It allows for quick, monthly checks to ensure the extinguisher is properly pressurized and ready to use.

-

Durable Construction: A high-quality dry powder extinguisher should have a metal valve, which is more durable and reliable than plastic components. A vehicle-specific model may come with a heavy-duty mounting bracket to secure it during travel.

English

English 中文简体

中文简体 Español

Español

VR Catalogue

VR Catalogue